From manufacturing to providing services: How does it transform?

-Kanakprabha Jethani | Executive

(kanak@vinodkothari.com)

Background

Servitization is that foreign business term that does not find place in any dictionary but is in steps to becoming essence of many businesses. It is a transformation, from manufacturing to providing solutions, from being product-centred to being complete-solution centred. Essentially, it is a business model in which, manufacturer of a product also engages in provision of services relating to that product.

The concept of servitization arises from the traditional ideology of business of maintaining life-long relationship with customers. Cranfield University defines servitization as “the innovation of organisation’s capabilities and processes to better create mutual value through a shift from selling product to selling Product-Service Systems.”

For instance, a laptop manufacturing company, say A Co. manufactures and sells “laptops”, it is a manufacturing concern. However, when A Co. sells a “package” which includes a laptop along with provision for after-sale services, software to support operations on the laptop, anti-virus software, cloud-space for data storage etc. it is said to be servitization.

How does this model operate? How do the parties earn? Are there any existing models operating? What is their structure of operation? Why does a manufacturer need to adopt this model? How will this be implemented? The following write-up answers all these questions and seeks to provide an all-round insight to the concept of servitization.

Structure of a servitization model

The concept of servitization has evolved answering the calls of the market that arose from phased transitions in customers approach to the products.

- Initially, a product-oriented market was prevalent in which the manufacturer and seller had just a buy and sell relationship. They became strangers right after the sale.

- This approach then shifted to product-oriented services, under which the manufacturer started providing additional services with respect to the product sold by it such as delivery, product installation, spare parts, updates and upgrades, warranty, maintenance etc.

- With Rolls Royce making leaps into innovation, the concept of use-oriented services came into place. Under this companies offer product leasing, sharing, renting, and pooling services where the customer pays fee for using the product.

This concept is however different from leasing as leasing provides exclusive rights to use to the lessee. In this model, the product can be shared between two or more customers or the owner and the customer.

- Later, the approach shifted to result-oriented services where the consideration for service provider is directly linked to the output generated by the customer.

Servitization model is a customer-oriented services model which combines features of all of the aforementioned approaches. This model serves the customers’ demand for real-time responses, effective self-service options, predictive maintenance etc.

An ideal servitization model involves an entire process from manufacturing of a product, its delivery, installation and training for its use to ongoing maintenance and consultancy relating to the product. It provides for an all-round cover of the product along with support services to the customer.

Money matters: How does the service-provider/manufacturer earn?

A typical servitization model of a manufacturer includes the following:

- Sustainable production process

- Supplier and customer interdependencies

- Lifetime product maintenance

- Repairs

- Recycling of end product

- Help desk

- Customer specific support agreements

An ideal servitization relationship includes incentives for the supplier to reduce costs. It shares risks, financial risk especially, and it is based on achieving the highest performance possible. The optimal contract consists of a fixed payment or fixed price, cost-sharing and performance-based compensation.

Through servitization, the seller is bound to provide services to the buyer till the product exists. This bond is achieved by tying the supplier’s compensation to the output value of the equipment generated by the customer. This creates a lasting relationship between the seller and buyer. This is the transformation from earning profits to creating mutual value.

Economics of servitization

For a business, the essence of servitization lies in establishing long-term relationship with customers. This lengthened relationship results in maintenance of steady revenues which then results in greater profitability and customer retention. Further, streamlining the supply and services reduces the risk of quality deterioration. To sustain in the market, it is very necessary to provide value addition. The market wants innovation and new offerings every day and has offerors all around. For a business to stay, will have to provide more than just a product. Providing aftersales services and advanced services such as consultancy services and solutions enables a business to meet customers’ demand for complete solution packages and thus ensures sustainability.

Further, through servitization, manufacturers are exposed to a whole new set of issues faced during operation of their products. This provides them insights for future R&D and helps them bring innovation in their products and ensure continuous product improvement.

For a customer, the prime benefit that servitization brings out is that the customer has to pay only for the value derived from the product. The customer is saved from risk of unproductive expenditure. Further, the quality of product is maintained as the manufacturing entity only does further servicing of the product. Since, the customer has to pay for what is operational, it also ensures that the ‘operational time’ is productive as well. This urges the customer to undertake profitable operations only.

Risks in servitization

- Financial risks: The transition from a manufacturing model to servitization model requires a complete shift in the operational basis of the entity. Also, the revenue generation model is completely changed by shifting the point of revenue generation from sale to outcome, which would result in elongation of operating cycle. Due to this, requirement of working capital is increased.

- Operational risks: Manufacturers face operational issues like how to assess the use of asset, level of maintenance required, frequency of updations etc. Further, the transition requires a complete turnaround in the operating team and procedures which involves a very long downtime.

- Partner risks: The concept of servitization is based on a generation of revenue when some other person is in operation. The return to manufacturer is directly linked with the operation or outcome of the customer. Thus, it poses a risk over the earning of the manufacturer.

Why does a business need to servitize?

For a business, where all competitors are trying to knock you down, survival is a lonely process. In order to stay, the business needs to keep the market interested. Following are certain factors which lead a business towards the direction of transformation:

- Economic rationale: In a competitive market, it is not possible for firms to compete on basis of cost as they already operate on very low margins. In such a case, innovation is the key to stand out from the competitors. Further, stability of revenues is yet another driving force in this direction.

- Strategic rationale: Through servitization, a business is able to retain its customers for a very long time. Lock-in customers and lock-out competitors is a clear implication of this. Moreover, customers are very much educated and aware in the present day market. They demand such models and a business that fulfils their demands, stays.

- Environmental rationale: The world is moving towards sustainability. Responding to the current environmental changes, if a single entity is engaged during the entire lifecycle of the product, it would result in preservation of resources to a great extent. A business with such values and respect towards the environment always achieves a higher place in the eyes of the customer.

Global examples

The philosophy of “co-existence” has laid its nets in the business also. The concept of mutual-benefit has become the new definition of profitability and the world is responding to this change in the following manner:

- Rolls Royce: This was the pioneering engine solution which changed the deal with customers from a transactional purchase of equipment towards a ten-year contractual relationship guaranteeing operational time of the engine. This model gave rise to the concept of ‘Performance-Based Logistics’ (PBL) which was initially introduced by Rolls Royce for jet engines. Later a similar model was proposed for the marine industry as well.

Under this model, a fixed amount for flying per hour is charged. The customer are provided with accurate projections for maintenance cost and assurance for avoidance of breakdown costs. - Xerox’s print management: This model offers a bundle of services and copier to the customer. It provides a comprehensive set of capabilities which prevent malicious attacks, proliferation of malware and misuse of unauthorised access to printers etc. as well as services to help better manage documentation. The customer is charged based on the number of sheets of paper they have copied or printed.

- MAN’s Financial Services: Offers comprehensive services around drivers’ behaviour and fuel efficiency in order to help customers operate more efficiently, with charging based on the distance trucks are driven.

This was launched with the basic motive of reducing the cost of lease during off-seasons. It enabled the lessee to pay certain sum on each kilometre travelled by the leased truckthereby reducing the downtime costs. - Lumenstream: This Britain based start-up provides customers with fully maintained LED lighting with no upfront cost. In line with the proven fact that LED lights save upto 60% energy costs, the customer is charged based on share of energy savings achieved over a period of five years.

- Small Robot Company: This company is transforming the process of farming through their Farming as a Service (FaaS) model. Under this model a series of robots (Tom, Dick and Harry) with ‘clever’ operating systems are linked to provide a full-fledged farming support. One of the robots monitors the crops, soil and weeds. The other two take care of all the feeding, seeding, and weeding. They record location of every crop and take care of each individual plant until it is entirely grown up.

The farmer does not need to make any upfront payment for leasing the robot. Instead the farmer is charged on the basis of per-hectare subscription fee of robots working. - Philips: Philips provides LED lighting as a service to Amsterdam Schiphol airport through ‘Internet of Things’ (IoT) connectivity. Under the arrangement, Philips takes responsibility of the performance of the LED lamps. On the other hand, the airport is able to save 50% energy cost by using LED lights. A share of saved cost is paid as consideration to Philips.

How has the world responded to servitization?

Penetration of servitization model: Country-wise

Servitization has been a buzz in the recent times. Some countries have already made it the core model of their businesses while some are still struggling to get familiar with the concept itself. To understand how servitization has impacted and will continue to impact the world, it is first important to understand, how deep servitization has spread its roots in business models of various countries.

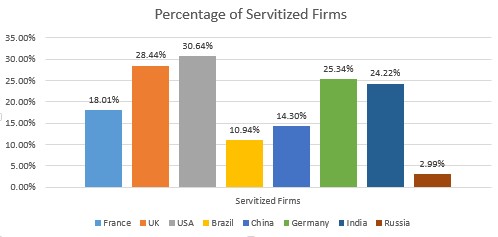

Following chart depicts that, out of certain number of entities, selected on random basis, what percentage of entities were practising servitization as on November 2013.

Source: University of Cambridge[1]

From the above figure it can be seen that USA has already embossed the concept of servitization in its ideology of business. A major chunk of the firms in USA covered by the research operate on servitization model. Seemingly, servitization model is in the steps of becoming the core model for majorly all businesses in USA. UK is following the footsteps of USA and has implemented servitization to some extent. Countries like Germany, India and France seem to be advancing in this field of innovation and some entities in these countries have initiated adopting servitization models. Russia seems to be resistant towards adoption of this innovation in its business models.

All that matters is growth

Benefits, growth, profits are the words that really matter in a business. Whether an innovation should be introduced or not? The answer lies in the benefits it gives. Businesses see benefits in growth and profitability. Increased sales, turnover, consumer base is what they look forward to.

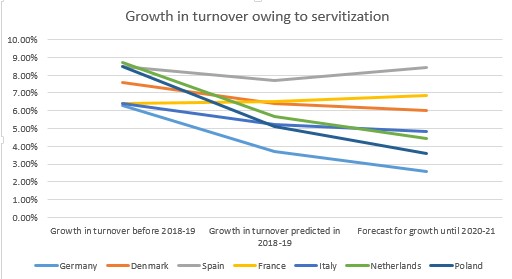

Following figure shows how servitization has effected the turnover growth in various countries and what the forecasts are for the near future.

Source: European Commission report on servitization

From its inception till 2018-19, the initial stages of implementation of servitization have shown the very high levels of growth in turnover for countries like Germany, Italy and Netherlands where servitization has been implemented upto reasonable levels. A study in France by European Commission shows that with 70% of SMEs in France being servitized, rate of employment also grew by 30% and an average annual increase of around 10% in turnover in the country was also witnessed. By 2020-21, when servitisation would already have been implemented in major countries, the pace of growth would tend to slow down. However, there are still no signs of negative growth forecasts in any of the countries. Servitization is expected to increase turnovers of various countries by averagely 3-4% in the coming years.

Striking the balance

Seemingly, the structure of servitization-based models is altogether a risky exertion. The manufacturer is exposed to huge risks as the consideration is based on the output of the customer. This might, on one hand, result in blocking of funds in the initial stages. While on the other hand, the customer base of the manufacturer is strengthened. Earning of the manufacturer depends on operations of the customer which are substantially out of the control of the manufacturer. This creates a gap in the chain of flow of income for the manufacturer.

The servitization model requires integration of operations of manufacturer and the customer. It calls for a close connection between the both. The manufacturer shall not only communicate with the person procuring the product, but also with the person actually engaged in operation of the product. The necessity of rethinking internal and external processes is highly felt while transforming from a product-based to a customer-based structure. Introduction of new technology and human resources specializing the service industry has to be the primary step in the transformation process. Extensive use of data and analytics is an inseparable part of servitization industry.

In essence, manufacturer will have to implement servitization as one major programme, which would address everything, from production processes to client communication and revenue generation. A risk-return balance will have to be achieved so that continuous inflow of income for the manufacturer is ensured.

Way forward

While some countries have implemented it to a large extent, some are advancing, some struggling and some oblivious to it, servitization seems to have entered all territories. Various sectors also have reacted differently to servitization, but reasonable growth has been recognised in all of them by now. Flaws would pop-up with time and would be handled accordingly. The concept of servitization is based on the principle of value for all. It has the potential to serve productivity and profitability at all levels of a value chain. Like every other innovation, operational aspects obviously have certain glitches which one can understand only after continuous operation. An effective implementation of servitization models would require consistent updations and modifications to achieve a feasible structure suitable to specific needs of both, the manufacturer and the customer. It’s a slow pathway to growth: Innovation and consistency are the keys.

[1]https://cambridgeservicealliance.eng.cam.ac.uk/resources/Downloads/Monthly%20Papers/2013November_ServitizationinGermany.pdf

Leave a Reply

Want to join the discussion?Feel free to contribute!